LD-series

Vollständig autonome mobile Roboter

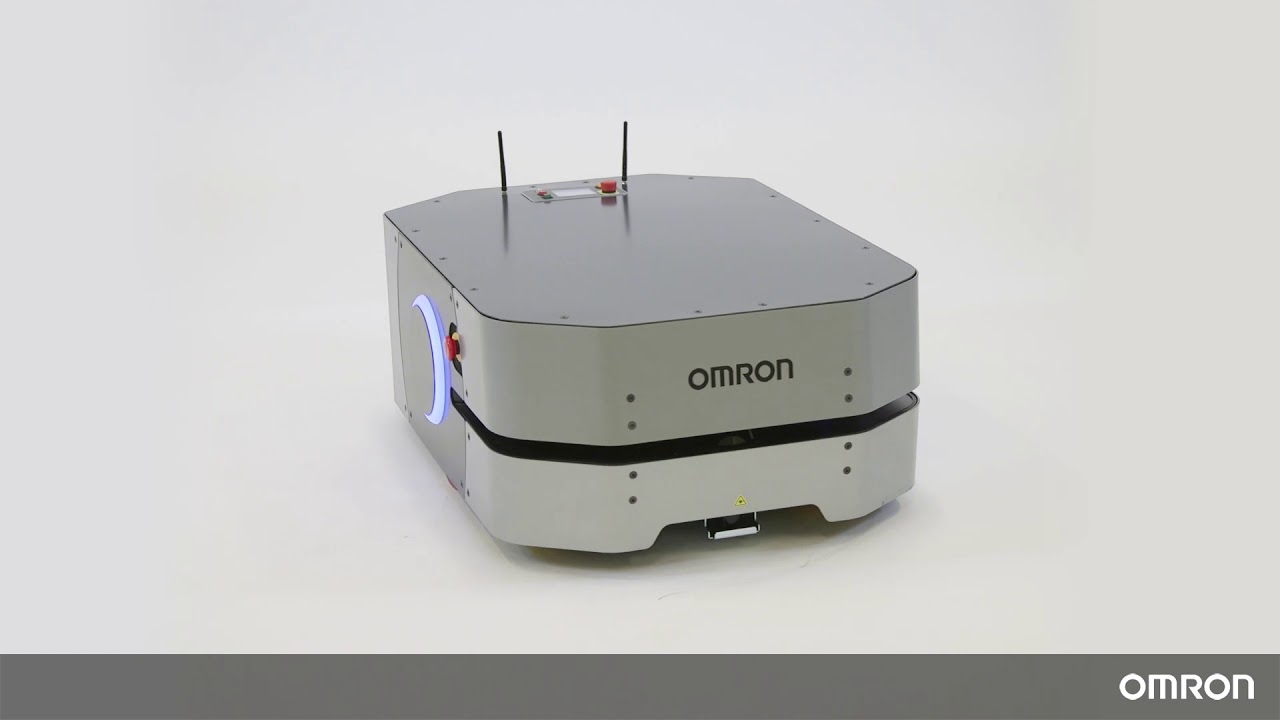

Mobile Roboter von OMRON sind autonome mobile Roboter (AMR), die die Produktivität in Fertigungs- und Logistikprozessen drastisch steigern. Unsere mobilen Roboter erhöhen den Durchsatz, vermeiden Fehler, verbessern die Materialrückverfolgbarkeit und sorgen dafür, dass Mitarbeiter sich auf Aufgaben konzentrieren können, die komplexe menschliche Fähigkeiten erfordern. Im Gegensatz zu herkömmlichen fahrerlosen Transportsystemen orientieren sich unsere mobilen Roboter an den räumlichen Gegebenheiten der Anlage und erfordern keine kostspieligen Umbauten.

-

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.

01:49

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.Selbstnavigierender autonomer mobiler Roboter (AMR)

Funktionen

Einfache Installation

-

1Einfache Entscheidungen und geringere KostenOMRON bietet ein Abonnementmodell, das niedrigere Einstiegskosten und kontinuierliche Upgrades und Verbesserungen bei der Bedienung von Funktionen bieten. Der Kunde kann Entscheidungen leichter treffen.

-

2Apps und Schaustücke auswählenOMRON hat mehrere Erfolgsfälle mit Schaustücken; der Vertrieb von OMRON kann Kunden bei der Wahl der besten Lösungen beraten.

-

3Zuordnung und ZielvereinbarungNach einem kurzen Rundgang durch Ihre Anlage erstellt der Roboter eine individuelle Karte des Grundrisses und legt Ziele für Abholungen und Rückgaben fest.

-

4Einfach zu bedienenDank der einfachen Bedienung per Tablet und der einfachen Integration zwischen dem OMRON-Flottenmanager und MES und WMS können Sie Ihre Roboter sofort in Betrieb nehmen.

Sicherheit

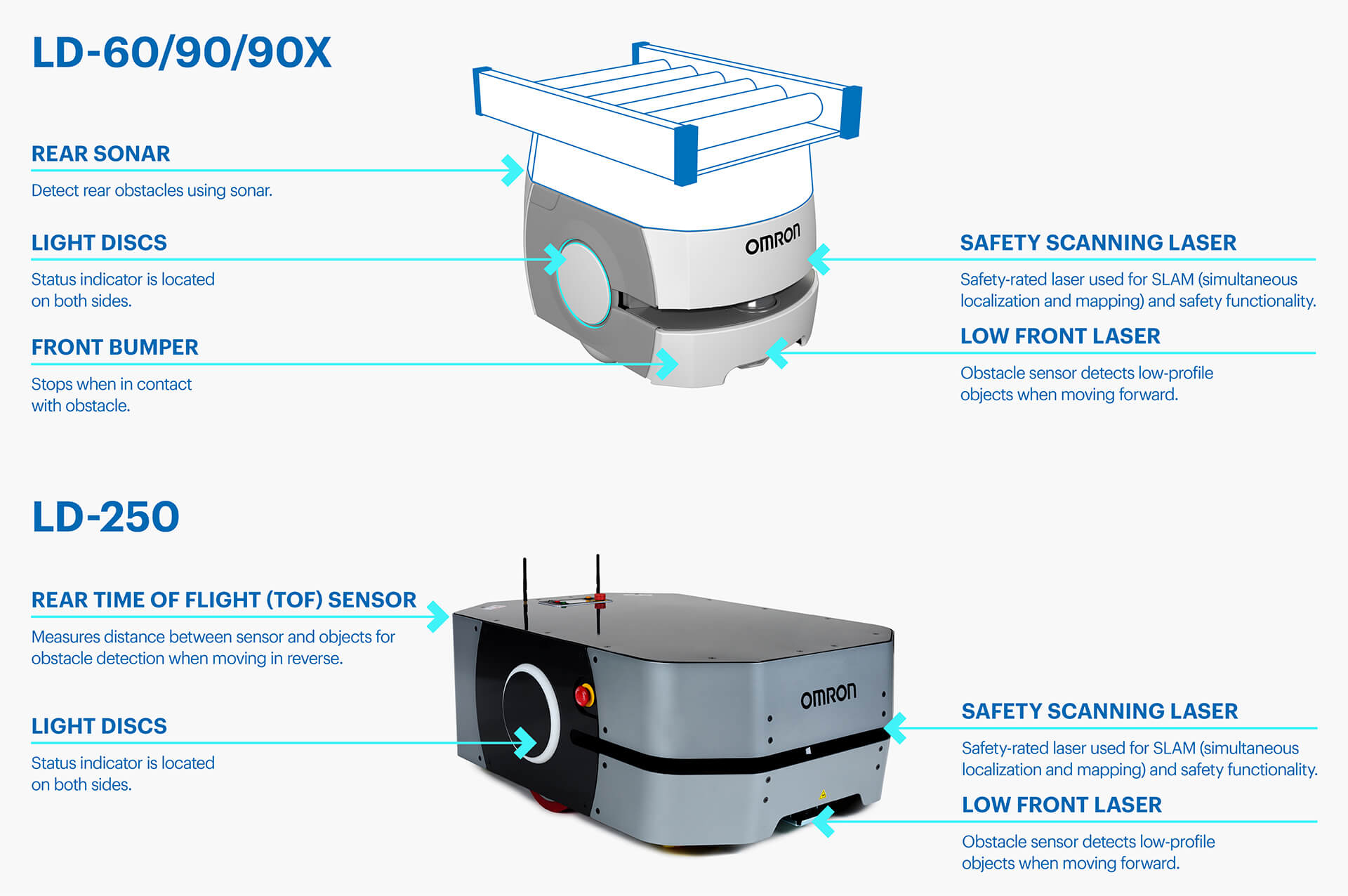

Die mobilen Roboter von Omron sind sicherheitsgeprüft. Sie verwenden eingebaute Laser und andere Sensoren, um auf den Fahrwegen Hindernisse zu erkennen. Je nach Fahrgeschwindigkeit kann ein Not-Halt ausgelöst werden, um zu verhindern, dass Fahrzeuge mit Objekten auf ihrem Weg kollidieren.

- LIDAR-Laser

- Unterer Laser

- Seitenlaser

- Frontstoßfänger

- Sonar

Sicherheitsfunktionen

-

1Weicht ortsfesten und beweglichen Hindernissen aus

-

2Zusätzliche Not-Halte können problemlos hinzugefügt werden

-

3Entspricht den Sicherheitsnormen ISO EN1525, JIS D6802 und ANSI B56.5

Technologie

AMR-Technologie und -Software

Die autonomen mobilen Roboter (Autonomous Mobile Robots, AMRs) von OMRON sind mit einer eigens für sie entwickelten Technologie ausgestattet, der AMR-Technologie für Navigation und Ausrichtung. Mithilfe dieser Technologie können sich die AMRs innerhalb ihres zugewiesenen Arbeitsbereichs selbst in komplexen Umgebungen sicher und effizient bewegen. Für den Betrieb der AMRs kommt zudem Software zum Einsatz, damit sie einfach verwendet und programmiert werden können.

- Die spezielle AMR-Technologie der AMRs von OMRON beinhaltet eine Vielzahl an Sensoren, z. B. Laserscanner. Diese ermöglichen es den Robotern, ihre Umgebung detailgetreu zu kartografieren und sich sicher zu bewegen.

- Die für den Betrieb der AMRs von OMRON genutzte Software ist benutzerfreundlich und intuitiv. So können die Roboter einfach für bestimmte Aufgaben programmiert werden.

Robuste Navigation

-

Omron's LD mobile robots automate material transport and increase efficiency - full version

Handling high-mix and low volume production, whilst compensating labour shortage are challenges for Omron manufacturing in Japan. See how LD mobile robots are used to automate material transport and increase efficiency, to accelerate human-machine collaboration.

03:47

Mobile robots smarten up Toyota’s new parts centre

Intelligent robots and sophisticated design are helping Toyota to achieve a higher level of efficiency at its new warehouse in Sydney, Australia.

Ausführungen

Plattformen LD-60, LD-90 und LD-90x

Unsere mobile OEM-Plattform steht Entwicklern und Maschinenbauern für kundenspezifische Anwendungen und Aufbau-Lösungen zur Verfügung. Sie umfasst unsere proprietäre Selbstnavigationssoftware, die sich ideal für den Einsatz in Bereichen mit viel Verkehr, engen Gängen und speziellen Anwendungen eignet, bei denen ein kompaktes autonom fahrendes Fahrzeug von Vorteil ist. Unsere OEM-Partner sind Entwickler von anwendungsspezifischen Aufbauten und vertrauen dabei auf unser zuverlässiges Antriebssystem, eine Bordstromversorgung, ein ausgereiftes Ladekonzept sowie Ein- und Ausgänge für die Integration ihrer Aufbauten in die mobile Plattform.

Die OEM-Mobilplattform von OMRON ist in drei Konfigurationen erhältlich, die alle eine Laufzeit von bis zu 19 Stunden pro Tag aufweisen:

- LD60 mit einer Transportkapazität von bis zu 60 kg (max. Geschwindigkeit 1,8 m/s)

- LD90 mit einer Transportkapazität von bis zu 90 kg (max. Geschwindigkeit 1,35 m/s)

- LD-90x: In einer Cart Transporter-Konfiguration erhöht sich die maximale Nutzlast auf bis zu 170 kg (max. Geschwindigkeit 0,9 m/s)

Plattform LD-250

- LD-250 mit einer Transportkapazität von bis zu 250 kg (max. Geschwindigkeit 1,2 m/s)

LD-250 Prospekt

ESD-Plattformen LD-60/90/90x/250

Die ESD-Roboter wurden für komplexe Produktionsumgebungen entwickelt und ermöglichen eine Erweiterung Ihrer automatisierten Anwendungen für die Materialabfertigung sowie gleichzeitigen Schutz. Sie wurden für den Schutz Ihrer ESDS-Produkte (Electrostatic Discharge Sensitive) konzipiert.

Die ESD-Verkleidungen bilden einen Schutzschild um den Roboter, der nicht nur Ihre Investitionen schützt, sondern auch statische Energie sicher an den Boden ableitet. Mit den mobilen ESD-Robotern der LD-Serie bieten wir eine sichere Lösung für den Umgang mit statisch empfindlichen Bauteilen.

- Gemeinsamer Schutz für Ihre ESDS-Produkte (Electrostatic Discharge Sensitive) und der LD-Serie.

- Entspricht IEC 61340-5-1 als statisch kontrollierte Oberflächen mit RG < 1 x 10^9.

- Schutz bei Feldstärken über ca. 40 kV/cm Luft.

- Die Verkleidungen sind für Unempfindlichkeit gegenüber elektrostatischen Entladungen konzipiert.

LD-250 ESD Prospekt

Spezifikationen & Bestellinfo

| Produkt | Mobile robot type | Maximum load | Maximum speed | Kit type | ESD protection | Battery included | Beschreibung | |

|---|---|---|---|---|---|---|---|---|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot only | No | No | Mobile Robot, LD-60, without Battery |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-60, Charger, without Battery |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-60, with Charger, without Battery, Joystick, Top Plate |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot only | Yes | No | Mobile Robot, LD-60, ESD, without Battery |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + docking kit | Yes | No | Mobile Robot Docking Station Kit, LD-60, ESD, Charger, without Battery |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + starter kit | Yes | No | Mobile Robot Starter Kit, LD-60, ESD, without Battery, with Charger, Joystick, Top Plate |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot only | No | No | Mobile Robot, LD-90, without Battery |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-90, Charger, without Battery |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-90, with Charger, without Battery, Joystick, Top Plate |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot only | Yes | No | Mobile Robot, LD-90, ESD, without Battery |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + docking kit | Yes | No | Mobile Robot Docking Station Kit, LD-90, ESD, Charger, without Battery |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + starter kit | Yes | No | Mobile Robot Starter Kit, LD-90, ESD, without Battery, with Charger, Joystick, Top Plate |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot only | No | No | Mobile Robot, LD-90x, without Battery |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-90x, Charger, without Battery |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-90x, with Charger, without Battery, Joystick, Top Plate |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot only | Yes | No | Mobile Robot, LD-90x, ESD, without Battery |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + docking kit | Yes | No | Mobile Robot Docking Station Kit, LD-90x, ESD, Charger, without Battery |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + starter kit | Yes | No | Mobile Robot Starter Kit, LD-90x, ESD,without Battery, with Charger, Joystick, Top Plate |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot only | No | No | Mobile Robot, LD-250, without Battery |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-250, with Charger, without Battery |

|

Zubehör

Wir helfen Ihnen gerne

Sie haben eine Frage? Unsere Experten unterstützen Sie gern bei jedem Schritt.

Ihr Kontakt LD-series

Vielen Dank für Ihre Anfrage. Wir setzen uns umgehend mit Ihnen in Verbindung.

Es liegen zur Zeit technische Probleme vor. Ihre Übertragung war nicht erfolgreich. Entschuldigen Sie dies bitte und versuchen es später noch einmal. Details

Angebot für LD-series

Über dieses Formular erhalten Sie ein Angebot zu Ihrem ausgewählten Produkt. Bitte füllen Sie alle Felder aus, die diese * Markierung besitzen. Ihre persönlichen Daten werden natürlich vertraulich behandelt.

Vielen Dank für Ihre Angebots-Anfrage, die wir schnellstmöglich beantworten werden.

Es liegen zur Zeit technische Probleme vor. Ihre Übertragung war nicht erfolgreich. Entschuldigen Sie dies bitte und versuchen es später noch einmal. Details

Lösungen

Mobile Manipulatorlösungen von Omron

Die einzigartige Konzeptlösung aus Cobot und mobilem Roboter-Hybrid von OMRON

Kundenbeispiele

-

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

03:30

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

-

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

03:11

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

-

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

03:32

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

-

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

02:36

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

-

UV-C robot helps businesses win the fight against Covid-19

As the UK’s customer-facing businesses plan their reopening strategies, keeping consumers and staff safe from Covid will be a key priority. In a bid to prevent future outbreaks at high footfall, everyday environments like supermarkets, bars and gyms, industrial automation specialist OMRON has teamed up with UV Systems UK, part of the Topline Group, to produce an autonomous robotic sterilisation system that guarantees to kill the virus without damage or harm to surrounding goods. The solution guarantees to eliminate viruses, pathogens and bacteria on all touchpoints within a facility, helping businesses to regain public confidence, relieve the burden on employees and meet regulations.

03:07

UV-C robot helps businesses win the fight against Covid-19

As the UK’s customer-facing businesses plan their reopening strategies, keeping consumers and staff safe from Covid will be a key priority. In a bid to prevent future outbreaks at high footfall, everyday environments like supermarkets, bars and gyms, industrial automation specialist OMRON has teamed up with UV Systems UK, part of the Topline Group, to produce an autonomous robotic sterilisation system that guarantees to kill the virus without damage or harm to surrounding goods. The solution guarantees to eliminate viruses, pathogens and bacteria on all touchpoints within a facility, helping businesses to regain public confidence, relieve the burden on employees and meet regulations.

-

Made-to-order production with an advanced fleet of mobile robots at VOLA

VOLA, a Danish manufacturer of luxury sanitary and kitchen fittings, has opened a new factory that incorporates a fleet of nine LD mobile robots from Omron. The new robot fleet works side-by-side with people, and is controlled by an advanced fleet management system. These have replaced roller conveyors, leading to a more flexible production and logistics set-up that matches the company’s single-piece production process, in which everything is produced to order.

02:36

Made-to-order production with an advanced fleet of mobile robots at VOLA

VOLA, a Danish manufacturer of luxury sanitary and kitchen fittings, has opened a new factory that incorporates a fleet of nine LD mobile robots from Omron. The new robot fleet works side-by-side with people, and is controlled by an advanced fleet management system. These have replaced roller conveyors, leading to a more flexible production and logistics set-up that matches the company’s single-piece production process, in which everything is produced to order.

-

Normagrup automates material transport with autonomous mobile robots

Founded in 1971, Normagrup is a world leader in technology dedicated to the production of interior lighting. Following the company’s original spirit and desire to create high-quality, technological products, they also apply this spirit in continuously improving their production processes. When Normagrup decided to automate material transport between production areas, they opted for a fleet of autonomous mobile robots with automatic loading and unloading stations. The project was carried out with Inser Robótica S.A. #mobilerobots #robotics #AMRs #intralogistics

02:21

Normagrup automates material transport with autonomous mobile robots

Founded in 1971, Normagrup is a world leader in technology dedicated to the production of interior lighting. Following the company’s original spirit and desire to create high-quality, technological products, they also apply this spirit in continuously improving their production processes. When Normagrup decided to automate material transport between production areas, they opted for a fleet of autonomous mobile robots with automatic loading and unloading stations. The project was carried out with Inser Robótica S.A. #mobilerobots #robotics #AMRs #intralogistics

-

Innovative production logistics at automotive manufacturer with Mini Smart Transport Robot MiniSTR

Innovative intralogistics application at the BMW Group with Mini Transport Robot, Omron LD mobile robot.

02:26

Innovative production logistics at automotive manufacturer with Mini Smart Transport Robot MiniSTR

Innovative intralogistics application at the BMW Group with Mini Transport Robot, Omron LD mobile robot.

-

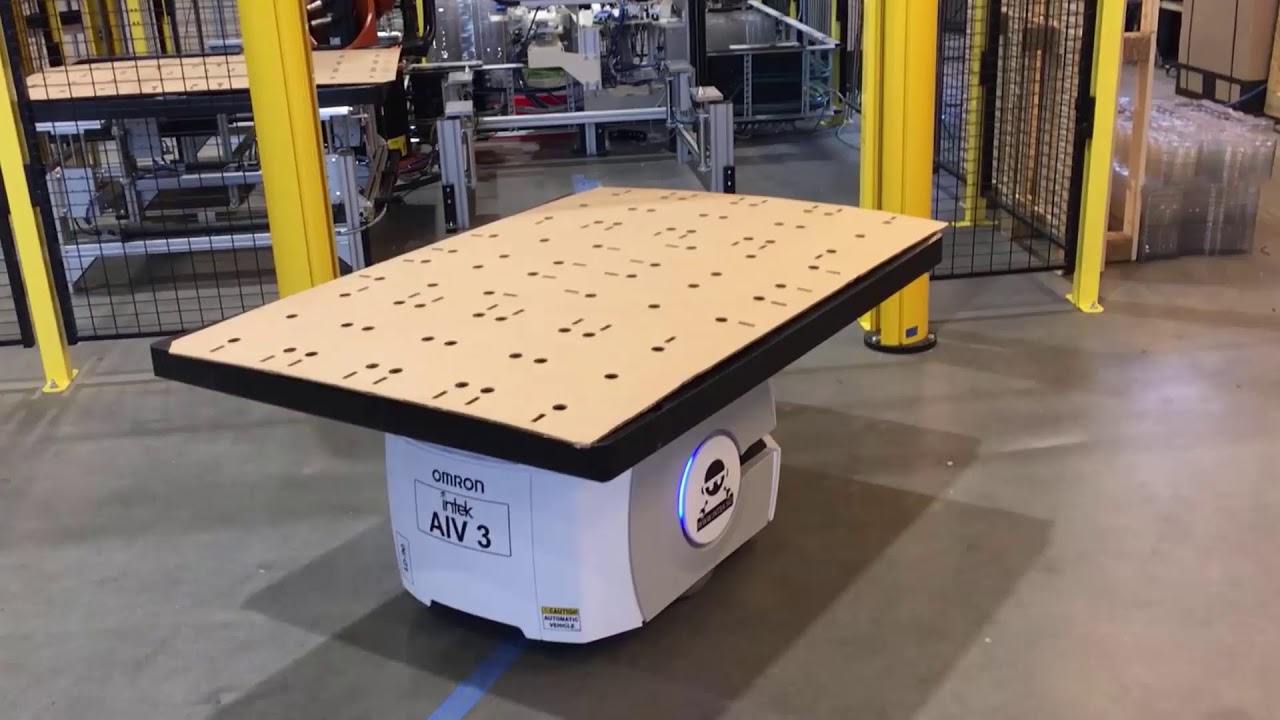

Mobile robots speed production at smart factory in Norway

Showcasing flexible production in real life, a new smart factory in Norway uses a variety of robots in a system developed and implemented by system integrator Intek Engineering. A dozen industrial robots, each in individual workstations or cells, perform different steps in the manufacturing process. Here is a demonstration from Intek Engineering on how the LD mobile robots from Omron can operate.

01:32

Mobile robots speed production at smart factory in Norway

Showcasing flexible production in real life, a new smart factory in Norway uses a variety of robots in a system developed and implemented by system integrator Intek Engineering. A dozen industrial robots, each in individual workstations or cells, perform different steps in the manufacturing process. Here is a demonstration from Intek Engineering on how the LD mobile robots from Omron can operate.

-

ŠKODA AUTO uses Omron's fully autonomous LD mobile robot at Vrchlabí plant

The autonomous robot contributes to the continuous improvement of work safety in Vrchlabí and helps to minimise work risks. It recognises people crossing its path as well as other vehicles and stationary obstacles.

03:00

ŠKODA AUTO uses Omron's fully autonomous LD mobile robot at Vrchlabí plant

The autonomous robot contributes to the continuous improvement of work safety in Vrchlabí and helps to minimise work risks. It recognises people crossing its path as well as other vehicles and stationary obstacles.

-

Customization and flexibility with high-speed manufacturing line and mobile robots at TePe

The oral hygiene manufacturer TePe has installed a new manufacturing line to replace its manual handling and quality inspection at their factory in Malmö, Sweden. A high-speed line from Omron comprising of industrial robots, mobile robots and vision systems now enables TePe to increase the throughput by 9 times and customise packaging for clients all over the world within seconds.

02:05

Customization and flexibility with high-speed manufacturing line and mobile robots at TePe

The oral hygiene manufacturer TePe has installed a new manufacturing line to replace its manual handling and quality inspection at their factory in Malmö, Sweden. A high-speed line from Omron comprising of industrial robots, mobile robots and vision systems now enables TePe to increase the throughput by 9 times and customise packaging for clients all over the world within seconds.

-

Mobile robot automates food distribution in a pilot at senior center

The Kustaankartano Senior Center in Finland is currently testing an autonomous mobile robot for automating food logistics between the Kustaankartano Food Centre and the senior centre. The pilot is being carried out in co-operation with Service Centre Helsinki; Helsinki Social Services and Health Care Division; and Forum Virium Helsinki. Its aim is to streamline the transport of meals to the senior centre's wards. The Polle (workhorse) robot developed by Dimalog Oy is based on OMRON’s autonomous LD-250 mobile robot. This is the strongest in the LD series of robots and can handle payloads of up to 250kg. It can navigate autonomously and is designed to interact with people to provide a collaborative and safe working environment.

03:01

Mobile robot automates food distribution in a pilot at senior center

The Kustaankartano Senior Center in Finland is currently testing an autonomous mobile robot for automating food logistics between the Kustaankartano Food Centre and the senior centre. The pilot is being carried out in co-operation with Service Centre Helsinki; Helsinki Social Services and Health Care Division; and Forum Virium Helsinki. Its aim is to streamline the transport of meals to the senior centre's wards. The Polle (workhorse) robot developed by Dimalog Oy is based on OMRON’s autonomous LD-250 mobile robot. This is the strongest in the LD series of robots and can handle payloads of up to 250kg. It can navigate autonomously and is designed to interact with people to provide a collaborative and safe working environment.

-

LD-250 autonomous mobile robot from OMRON in a pallet wrapping application

OMRON's LD-250 autonomous mobile robots (AMRs) are designed to dramatically increase productivity in manufacturing and logistics operations. They increase throughput, eliminate errors, improve material traceability, and allow employees to focus on tasks that require complex human skills. And, unlike traditional AGVs, these mobile robots navigate by the natural features of the facility and require no expensive facility modification. In this video, the mobile robot, that can carry payloads of up to 250kg, is used in an automated pallet wrapping application. For more information, please visit:

02:02

LD-250 autonomous mobile robot from OMRON in a pallet wrapping application

OMRON's LD-250 autonomous mobile robots (AMRs) are designed to dramatically increase productivity in manufacturing and logistics operations. They increase throughput, eliminate errors, improve material traceability, and allow employees to focus on tasks that require complex human skills. And, unlike traditional AGVs, these mobile robots navigate by the natural features of the facility and require no expensive facility modification. In this video, the mobile robot, that can carry payloads of up to 250kg, is used in an automated pallet wrapping application. For more information, please visit:Videos

-

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

01:43

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

-

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

00:53

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

01:09

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

-

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.

03:21

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.

-

OMRON Mobile I/O Box Tutorial Video

The OMRON Mobile I/O Box is an I/O device that can be used to summon an autonomous mobile robot (AMR) to a designated location by just pressing a button. #mobilerobots #omronindustrialautomation

08:56

OMRON Mobile I/O Box Tutorial Video

The OMRON Mobile I/O Box is an I/O device that can be used to summon an autonomous mobile robot (AMR) to a designated location by just pressing a button. #mobilerobots #omronindustrialautomation

-

Omron's LD mobile robots automate material transport and increase efficiency - full version

Handling high-mix and low volume production, whilst compensating labour shortage are challenges for Omron manufacturing in Japan. See how LD mobile robots are used to automate material transport and increase efficiency, to accelerate human-machine collaboration.

03:47

Omron's LD mobile robots automate material transport and increase efficiency - full version

Handling high-mix and low volume production, whilst compensating labour shortage are challenges for Omron manufacturing in Japan. See how LD mobile robots are used to automate material transport and increase efficiency, to accelerate human-machine collaboration.

-

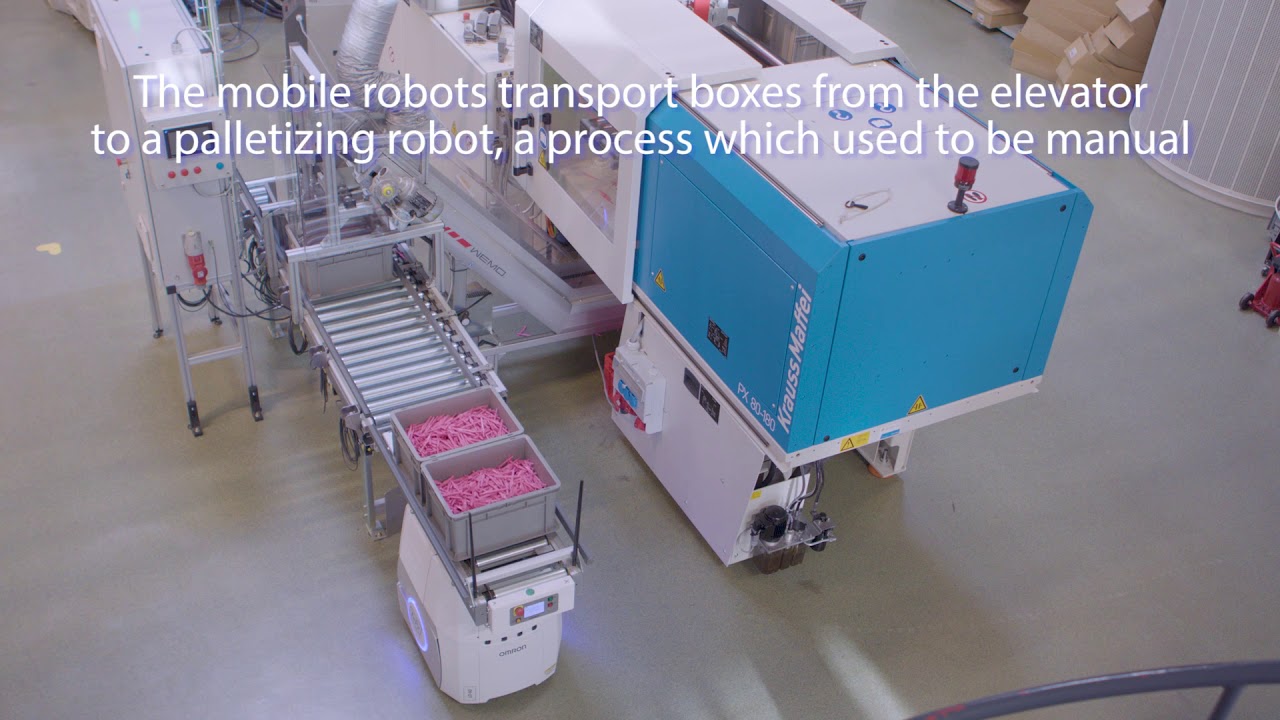

OMRON LD-60/90 Mobile Robots with Flexible Box Navigation

Introducing the OMRON LD-60/90 Mobile Robots with top conveyor for box handling. LD Top Conveyor for seamless interaction between robots, machines and humans enables production runs to be quickly and easily adjusted. MObile Robots can be equipped with tops or add-ons to carry out various tasks such as lifts to conveyors or even custom add-ons. Learn more about the OMRON LD-60/90 Mobile Robot

02:44

OMRON LD-60/90 Mobile Robots with Flexible Box Navigation

Introducing the OMRON LD-60/90 Mobile Robots with top conveyor for box handling. LD Top Conveyor for seamless interaction between robots, machines and humans enables production runs to be quickly and easily adjusted. MObile Robots can be equipped with tops or add-ons to carry out various tasks such as lifts to conveyors or even custom add-ons. Learn more about the OMRON LD-60/90 Mobile Robot

-

OMRON FLOW Core 3.0 MobilePlanner Tablet

The MobilePlanner tablet edition is an easy-to-use interface designed to monitor and control your Mobile Robot fleet from a tablet. #omronindustrialautomation #mobilerobots

00:46

OMRON FLOW Core 3.0 MobilePlanner Tablet

The MobilePlanner tablet edition is an easy-to-use interface designed to monitor and control your Mobile Robot fleet from a tablet. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Dynamic Obstacle Tracking

Collaborative and intuitive robot motion with “pass-behind” decision making for a better decision-making and path planning. #omronindustrialautomation #mobilerobots

00:34

OMRON FLOW Core 3.0 Dynamic Obstacle Tracking

Collaborative and intuitive robot motion with “pass-behind” decision making for a better decision-making and path planning. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Cell Alignment Positioning System (CAPS)

CAPS technology utilizes any compatible laser to detect a customizable target in the environment and enables the AMR to drive to the required location with unrivalled precision. #omronindustrialautomation #mobilerobots

00:46

OMRON FLOW Core 3.0 Cell Alignment Positioning System (CAPS)

CAPS technology utilizes any compatible laser to detect a customizable target in the environment and enables the AMR to drive to the required location with unrivalled precision. #omronindustrialautomation #mobilerobots

LD-250 mobile robot tutorial 2 - Add the robot to your fleet

-

LD-250 mobile robot tutorial 1- Getting started

In this video, you can learn how to get started with the LD-250, from unboxing the mobile robot to getting it on your wireless network, and connecting to the MobilePlanner. Get your LD-250 ready to go!

06:42

LD-250 mobile robot tutorial 1- Getting started

In this video, you can learn how to get started with the LD-250, from unboxing the mobile robot to getting it on your wireless network, and connecting to the MobilePlanner. Get your LD-250 ready to go!

-

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.

01:49

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.

-

Mobile robot cart transporter solution for payloads of up to 500kg

How can innovative and safe material flow contribute to creating the factory of the future? In traditional material flow processes there are many safety concern and risks, especially when operating in narrow environments, surrounded by operators. Forklifts and tugger trains are always a safety risk when working in the same area with people. How can a solution with autonomous mobile robots help ensure safety while improving efficiency and flexibility in material flow processes? The OMRON LD-250 autonomous mobile robot can be upgraded to double its usual payload from 250kg to up to 500kg by integrating into a Cart Transporter version. The user can design a custom latching system and cart based on their specific needs. The solution ensures full safety, flexibility and just-in-time delivery of goods. For more information, visit:

01:05

Mobile robot cart transporter solution for payloads of up to 500kg

How can innovative and safe material flow contribute to creating the factory of the future? In traditional material flow processes there are many safety concern and risks, especially when operating in narrow environments, surrounded by operators. Forklifts and tugger trains are always a safety risk when working in the same area with people. How can a solution with autonomous mobile robots help ensure safety while improving efficiency and flexibility in material flow processes? The OMRON LD-250 autonomous mobile robot can be upgraded to double its usual payload from 250kg to up to 500kg by integrating into a Cart Transporter version. The user can design a custom latching system and cart based on their specific needs. The solution ensures full safety, flexibility and just-in-time delivery of goods. For more information, visit:Downloads

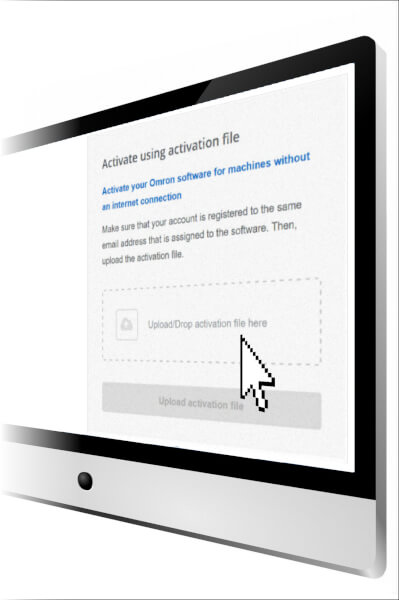

Ihre mobile Robotersoftware aktivieren

Fordern Sie die Aktivierung Ihrer Lizenzen für mobile Roboterlösungen einfach online an. Bitte verwenden Sie dieses Formular, um eine Lizenzaktivierung für die mobile Roboterlösung auf den verschiedenen Geräten zu beantragen: Geräte der LD-Serie, der MD-Serie oder der HD-Serie sowie EM2100 und virtueller Flottenmanager.

Sie brauchen Unterstützung?

Wir helfen Ihnen gerne! Sprechen Sie uns an, und unsere Experten helfen Ihnen, die beste Lösung für Ihr Unternehmen zu finden.

Ihr Kontakt LD-series

Vielen Dank für Ihre Anfrage. Wir setzen uns umgehend mit Ihnen in Verbindung.

Es liegen zur Zeit technische Probleme vor. Ihre Übertragung war nicht erfolgreich. Entschuldigen Sie dies bitte und versuchen es später noch einmal. Details

Angebot für LD-series

Über dieses Formular erhalten Sie ein Angebot zu Ihrem ausgewählten Produkt. Bitte füllen Sie alle Felder aus, die diese * Markierung besitzen. Ihre persönlichen Daten werden natürlich vertraulich behandelt.

Vielen Dank für Ihre Angebots-Anfrage, die wir schnellstmöglich beantworten werden.

Es liegen zur Zeit technische Probleme vor. Ihre Übertragung war nicht erfolgreich. Entschuldigen Sie dies bitte und versuchen es später noch einmal. Details

_reference_manual_en.jpg)

_leaflet_en.jpg)